1 / 3

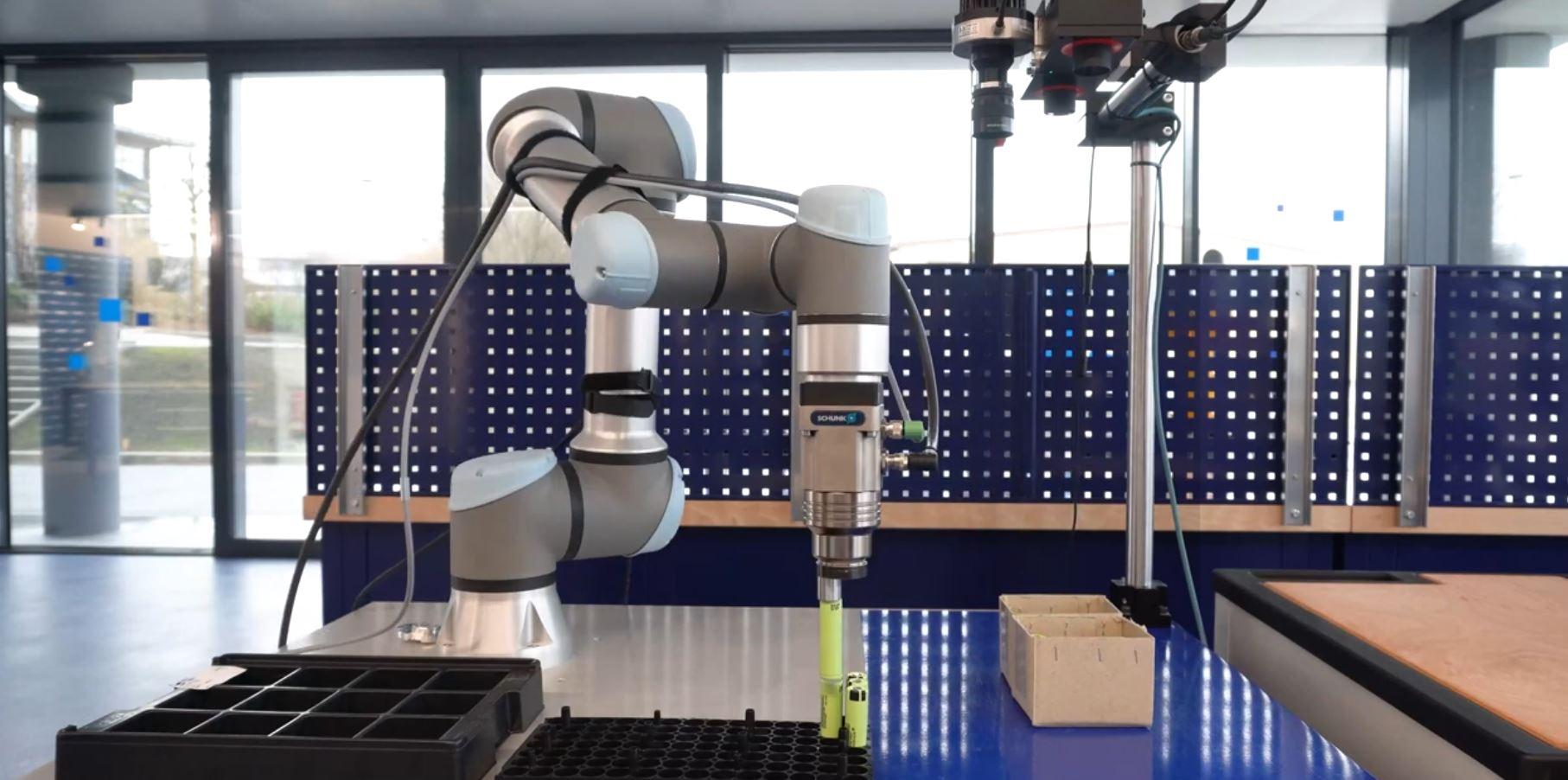

1 / 3Vision based Pick and Place application with rotary gripper

Hardware Price:

Max Acceleration

20

m⁄s²

Repeatability

0.5

mm

DOF

3

Delta Robot Cell: Precision and Efficiency in Small Component Handling

Handling small components in manufacturing demands high accuracy and efficiency to ensure streamlined workflows. In this customer test, a delta robot cell is demonstrated, utilizing a pneumatic rotary gripper and camera system for precise operations. Components placed on a conveyor belt are tracked by the camera, which captures exact positions and provides coordinate data to the robot. Guided by this input, the delta robot reliably grips the components and places them in consistent orientations, showcasing the advantages of modern automation technologies.

What is the Application?

The system automates small component handling on conveyor belts, enabling accurate positioning and placement in manufacturing and assembly processes.

What are the Advantages of the Solution?

Enhanced Precision: Camera-guided movements guarantee accurate gripping and placement.

Uninterrupted Workflow: Automated operation ensures consistent productivity.

Versatile Integration: Compact design fits seamlessly into various production environments.

What are the Advantages of the Robot?

The delta robot delivers reliable performance:

Exact Movements: Pneumatic rotary gripper ensures precise handling.

Flexibility: Adjusts effortlessly to different component sizes and layouts.

Speed and Efficiency: Processes parts quickly without compromising accuracy.

Modernizing Assembly with Delta Robot Technology

This delta robot cell demonstrates how automation enhances productivity in handling small components. Combining camera systems, precise robot movements, and innovative gripping technology, it sets new benchmarks for accuracy and efficiency, making it a vital tool for advanced manufacturing solutions.

3 Components