1 / 4

1 / 4ReBeL 6 axis robot for restaurant automation

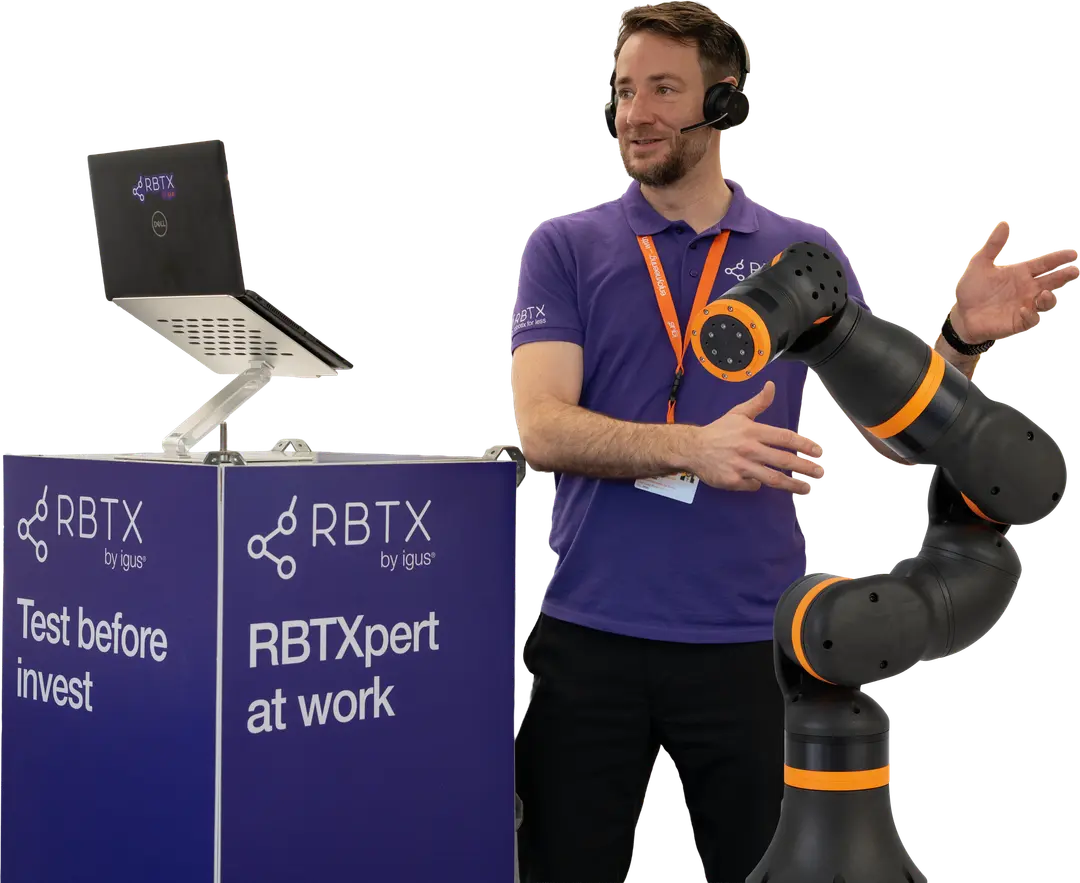

Test before Invest

Hardware Price:

DOF

6

Max. range

660

mm

Repeatability

1

mm

Efficient Food Packaging with igus ReBeL: Automation for the Fast-Food Industry

This test demonstrates how igus ReBeL cobots optimize workflows in food production by handling and transporting fast-food products via a conveyor belt. Using jointed-arm robots, the system efficiently transfers pre-boxed items through various production stages, showcasing the scalability of automated solutions. The ReBeL cobot’s flexibility enables streamlined processes for packaging, sorting, and distribution.

What is the Application?

The system automates food handling and transportation, allowing production lines of variable lengths to adapt to diverse fast-food industry needs, ensuring efficiency and high throughput.

What are the Advantages of the Solution?

Scalable Setup: Easily expandable production lines for varied requirements.

Time Saving: Faster workflows and reduced reliance on manual labor.

Simple Integration: Free igus Robot Control software ensures effortless programming.

What are the Advantages of the Robot?

The igus ReBeL cobot provides reliable performance for food industry tasks:

Precision Handling: 6-axis motion delivers consistent results.

Flexible Configuration: Optional drylin® seventh axis expands reach and adaptability.

Cost-Efficiency: Affordable, certified low-cost automation solution.

Transforming Food Production with Scalable Automation

The igus ReBeL cobot enables food packaging systems to operate efficiently and flexibly. Its precision, scalability, and cost-effectiveness make it an ideal solution for fast-food production lines, supporting productivity and simplifying operations while maintaining high-quality results.

2 Components