1 / 5

1 / 5Pick and Place Robot to Aid in Production of Fire-Resistant Glass

Hardware Price:

Project costs

15,000

GBP

ROI

12

Months

Pick rate

30

Picks per minute

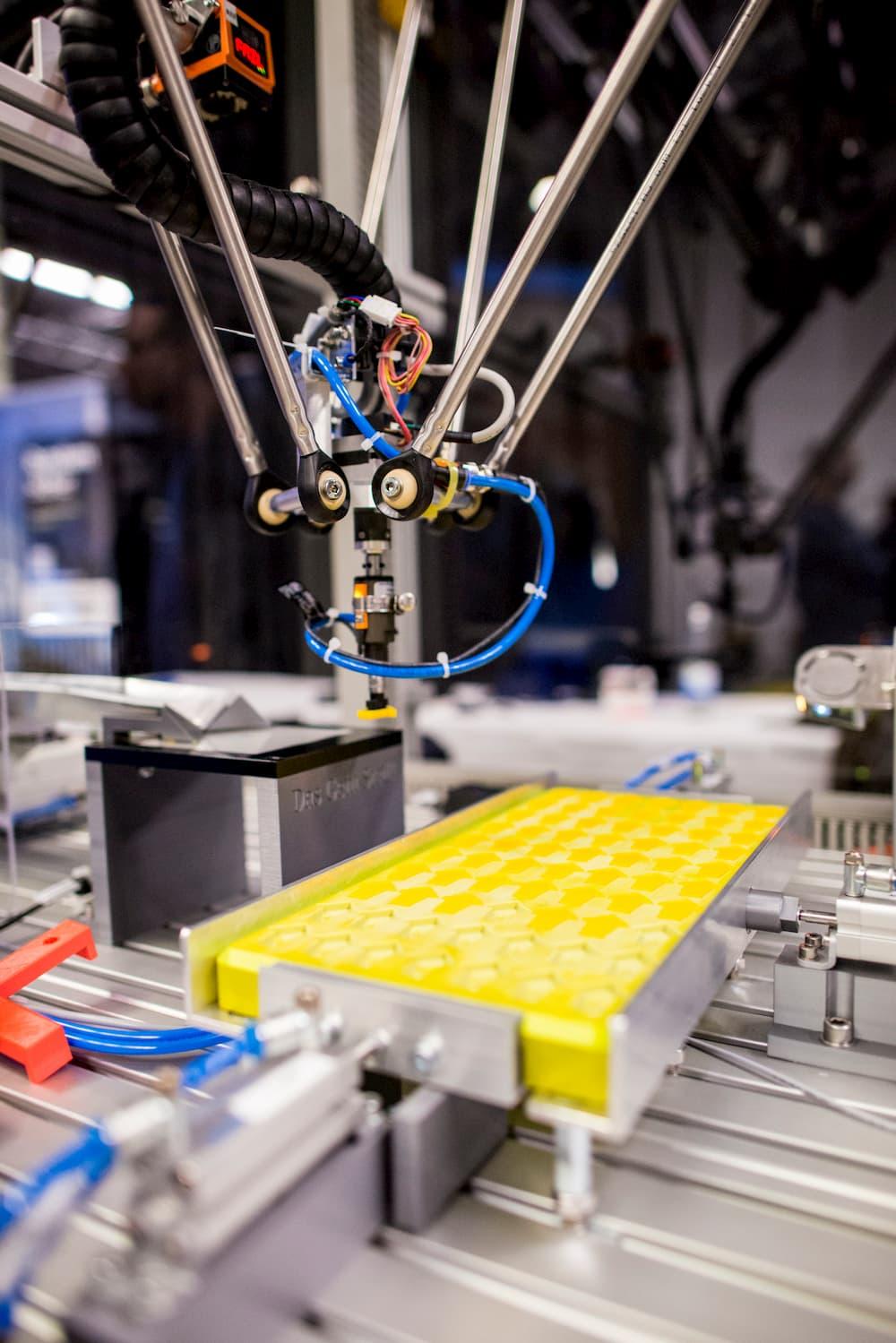

Efficient Sorting with Delta Robot: Automation in Glass Production

Vetrotech Saint-Gobain Kinon GmbH, a global leader in safety and high-tech glass production, has optimized its workflow for producing fire-resistant glass. The process previously relied on manual labor to place plastic components in molds as placeholders. To improve efficiency and reduce employee strain, the company implemented an igus Delta robot equipped with a suction cup, achieving a maximum pick rate of 30 picks/min for sorting bulk material on predefined pallets.

What is the Application?

The Delta robot automates the sorting and placement of plastic placeholders into molds, eliminating the need for repetitive manual tasks in the production process.

What are the Advantages of the Solution?

Employee Relief: Reduces strain from monotonous work, freeing up employees for complex tasks.

Cost Efficiency: Pays for itself within 12 months due to reduced labor dependency.

Enhanced Production Speed: Accelerates sorting processes while maintaining reliable results.

What are the Advantages of the Robot?

The igus Delta robot delivers robust performance:

High Precision: Suction technology ensures secure and accurate positioning.

Fast Operation: Handles up to 30 picks/min, optimizing workflow.

Low Maintenance: Durable design requires minimal servicing.

Streamlining Glass Manufacturing with Automated Sorting

The integration of the igus Delta robot has transformed sorting tasks at Vetrotech Saint-Gobain Kinon GmbH, improving work quality and boosting production speed. By automating repetitive processes, the company enhances efficiency, reduces costs, and ensures employees can focus on value-adding activities—an ideal solution for modern glass manufacturing.

2 Components